Welcome to Our Company

SMPS Aging Test Machine with 200W/CH Power CC+CV Load Mode and Temperature Monitoring Burn-In Test Cabinet

6500.0 USD ($)/Set

Product Details:

- Frequency 50Hz Hertz (HZ)

- Accuracy 0.5% F.S. %

- Humidity 20% to 90% RH

- Equipment Type Aging Test Machine

- Gas Pressure 0.5-0.8 MPa mpa

- Power Supply AC 220V, 50Hz

- Port Size Standard Test Interface

- Click to view more

X

SMPS Aging Test Machine with 200W/CH Power CC+CV Load Mode and Temperature Monitoring Burn-In Test Cabinet Price And Quantity

- 1 Set

- 6500.0 USD ($)/Set

- Audio-visual fault alarm

- Forced Air Cooling

- Short circuit and overload protection, emergency stop

- Indoor, dust free

- Supports USB data export, onboard memory

- Supports programmable test cycles and modes

- Blue with white finish

SMPS Aging Test Machine with 200W/CH Power CC+CV Load Mode and Temperature Monitoring Burn-In Test Cabinet Product Specifications

- 1200 mm

- 400 Kg

- RS232/USB

- Digital LCD Display

- Automatic timing, statistics, over-current/over-voltage protection

- 600 mm Foot (ft)

- Laboratory/Production Line Testing

- Max 70 x 70 x 150 mm Millimeter (mm)

- AC 220V Volt (V)

- Charger and Power Supply Aging Testing

- Floor Standing

- 0-200 mm adjustable

- 50Hz Hertz (HZ)

- 0.5% F.S. %

- 20% to 90% RH

- 0.5-0.8 MPa mpa

- Aging Test Machine

- AC 220V, 50Hz

- Standard Test Interface

- 0-300V Celsius (oC)

- Automatic

- 0-30A

- 400 Kilograms (kg)

- 0-120 cycles/min adjustable

- Up to 40 channels

- 100ms Minutes

- 10 C to 40 C Planck temperature ()

- 0.01A / 0.01V

- PLC Automatic Control

- Audio-visual fault alarm

- Forced Air Cooling

- Short circuit and overload protection, emergency stop

- Indoor, dust free

- Supports USB data export, onboard memory

- Supports programmable test cycles and modes

- Blue with white finish

SMPS Aging Test Machine with 200W/CH Power CC+CV Load Mode and Temperature Monitoring Burn-In Test Cabinet Trade Information

- 200 Set Per Month

- 20-25 Days

Product Description

Based on the skills of our adroit professionals, we are able to offer a wide range of Charger Power Supply Aging Test Machine. The offered test machine is broadly acclaimed by our clients for its optimum quality, sturdiness and high performance. Our talented workers, with hard-earned experience in their respected field manufacture this test machine fulfilling all parameters of quality. Apart from this, our offered Charger Power Supply Aging Test Machine is delivered to the customers only after checking completely to eradicate any possible flaw.

Product parameters

| Model | CP-3006 | CP-3008 | CP-3009 | CP-3010 |

| Power of single channel | 200W/CH | 150W/CH | 100W/CH | 65W/CH |

| Quantity of load channels |

192CH | 192CH | 192CH | 192CH |

| Scope of load voltage | 2-100V | 2-100V | 2-100V | 2-100V |

| Scope of load current | 0.2-10A/CH | 0.2-10A/CH | 0.2-10A/CH | 0.2-10A/CH |

| Load precision | 1%+0.1%FS | 1%+0.1%FS | 1%+0.1%FS | 1%+0.1%FS |

| Load Model | Energy Saving | Energy Saving | Energy Saving | Energy Saving |

| Load Mode | CC+CV Mode | CC+CV Mode | CC+CV Mode | CC+CV Mode |

| Number for plies of product zone |

Single side | Single side | Single side | Single side |

| Height for plies of product zone(mm) |

170 | |||

| Width of products zone(mm) |

Series CC mode 340 | |||

| Temperature control of products zone |

Temperature control type of products zone: normal temperature-60 | |||

| Structure material of trolley |

Elaborately processed and produced with cold-rolled sheet | |||

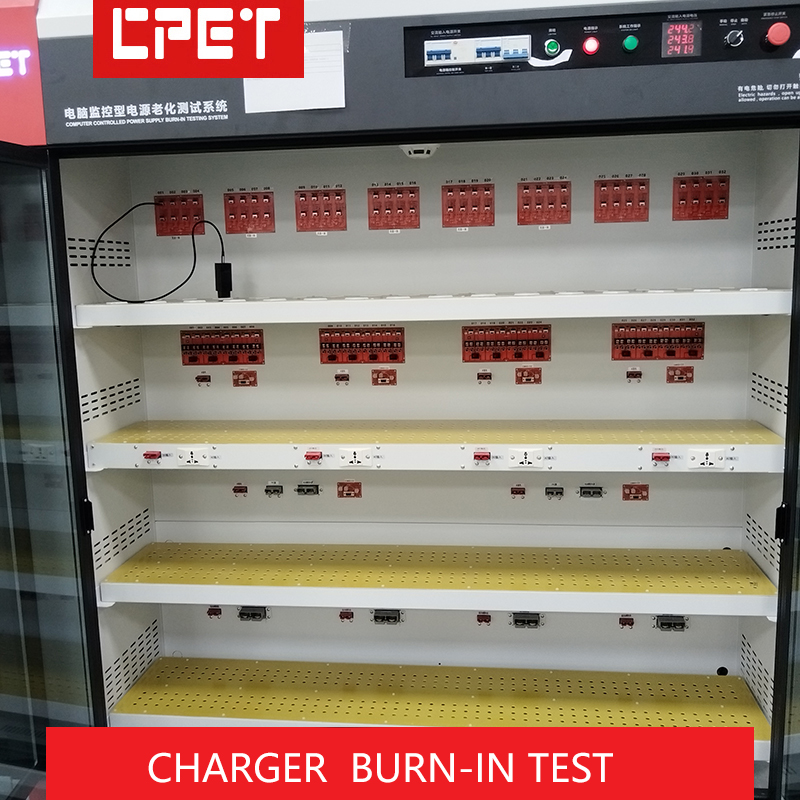

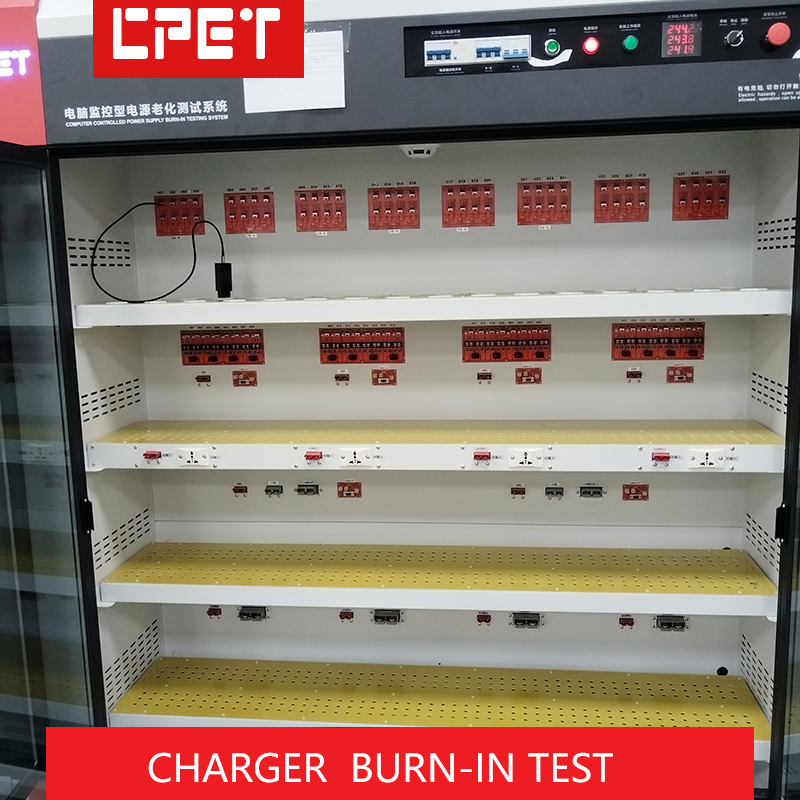

| Mode of main control | Monitoring software for burn-in of computer-monitoring type power | |||

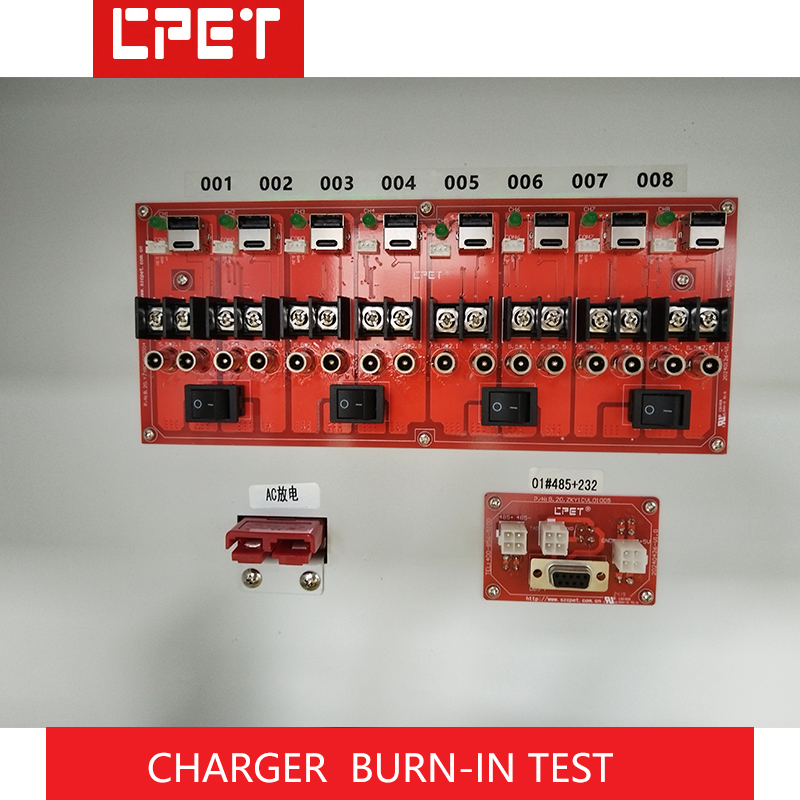

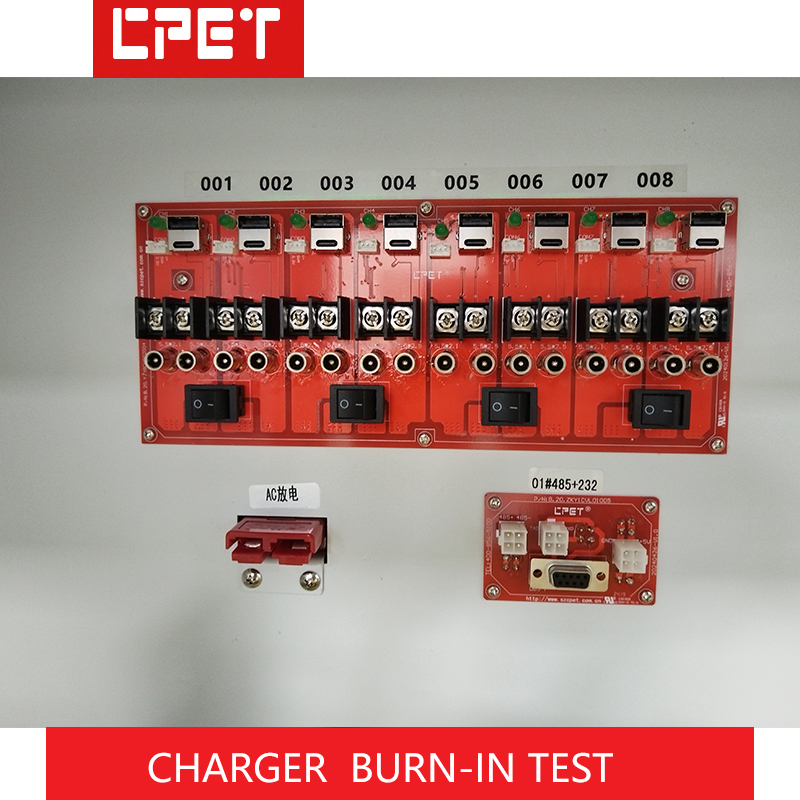

| Input mode of UUT | Multi-purpose socket/speaker wire clip/custom design | |||

| Interface mode of UUT | Connecting fixture boards (with various specifications) for first choice/custom design | |||

| Customizable fast charge function |

QC, PO, FCP, SCP, PPS, etc. | |||

| External dimension | 2050*880*1900/custom design | |||

Advanced Programmable Test Cycles

This aging test machine allows users to configure customizable test cycles and modes, providing flexibility for different charger or power supply testing requirements. Its PLC automatic control streamlines the process, enhancing productivity while maintaining operational consistency.

Comprehensive Data Management

Store critical test data on the onboard memory or export it conveniently via USB. The RS232/USB interface ensures seamless data transfer for further analysis or reporting, essential for quality control and compliance documentation.

Enhanced Safety and Reliability

The system integrates audio-visual alarms, as well as advanced short circuit and overload protections. With a reliable emergency stop button, operators can halt testing instantly, ensuring a secure environment and protection for both users and specimens.

FAQs of Charger Power Supply Aging Test Machine:

Q: How does the machine ensure safety during aging tests?

A: The test machine is equipped with short circuit and overload protection mechanisms, along with an emergency stop function. These features, combined with audio-visual alarms, minimize potential hazards and provide immediate alerts in case of a fault.Q: What is the process for exporting test data?

A: Users can export testing data directly from the onboard memory using the USB interface. Additionally, the RS232 port offers another data export option, allowing for easy integration with quality assurance workflows or analysis software.Q: Where is the best environment to install this aging test machine?

A: Install the equipment indoors in a clean, dust-free facility. The recommended environmental conditions are a temperature range of 10C to 40C and humidity between 20% and 90% RH, ensuring optimal performance and equipment longevity.Q: When should I utilize different test cycles and modes?

A: Programmable test cycles and modes should be selected based on the specific type and requirements of the chargers or power supplies being tested. This flexibility allows for customized testing scenarios to match diverse product specifications or production stages.Q: What are the main benefits of forced air cooling in this machine?

A: Forced air cooling ensures stable internal temperatures during intensive aging tests, preventing overheating and promoting the consistent performance of electronic components throughout extended operation periods.Q: How many specimens can be tested at the same time?

A: The machine supports simultaneous testing of up to 40 channels, accommodating specimens with maximum dimensions of 70 x 70 x 150 mm, which is ideal for batch testing in production environments.Q: What is the range of parameters that can be adjusted for testing?

A: Operators can adjust test speed (0120 cycles/min), test width (up to 600 mm), and test stroke (0200 mm). The system covers measuring ranges from 0300V and 030A, with high resolutions of 0.01A/0.01V, catering to varied testing needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese